Polydexter 1.0

Project Team: Jeff Maeshiro, Jia Wu

Advisors: Jason Kelly Johnson and Michael Shiloh, California College of the Arts

Location: San Francisco, California, USA

Year: 2013

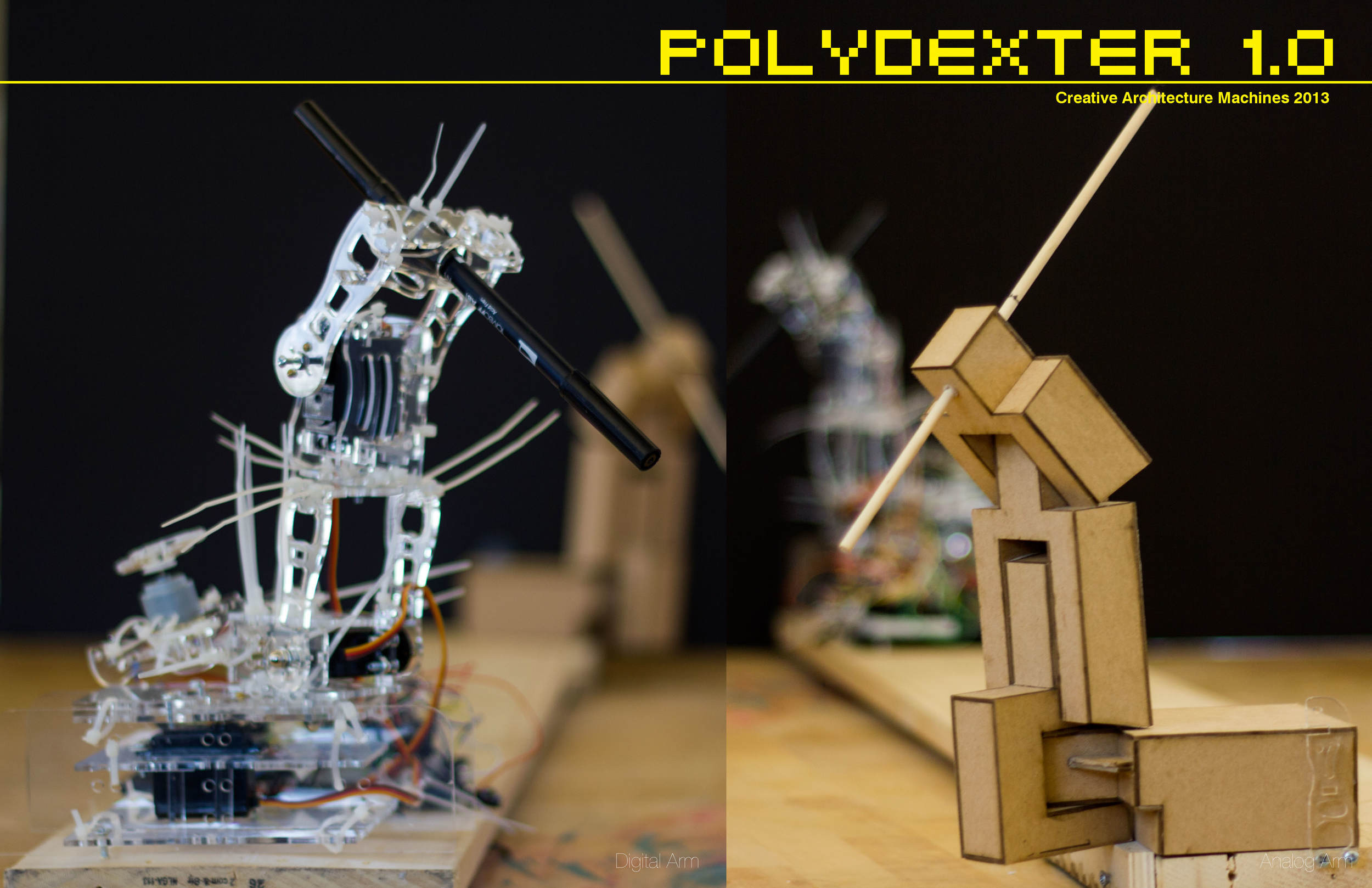

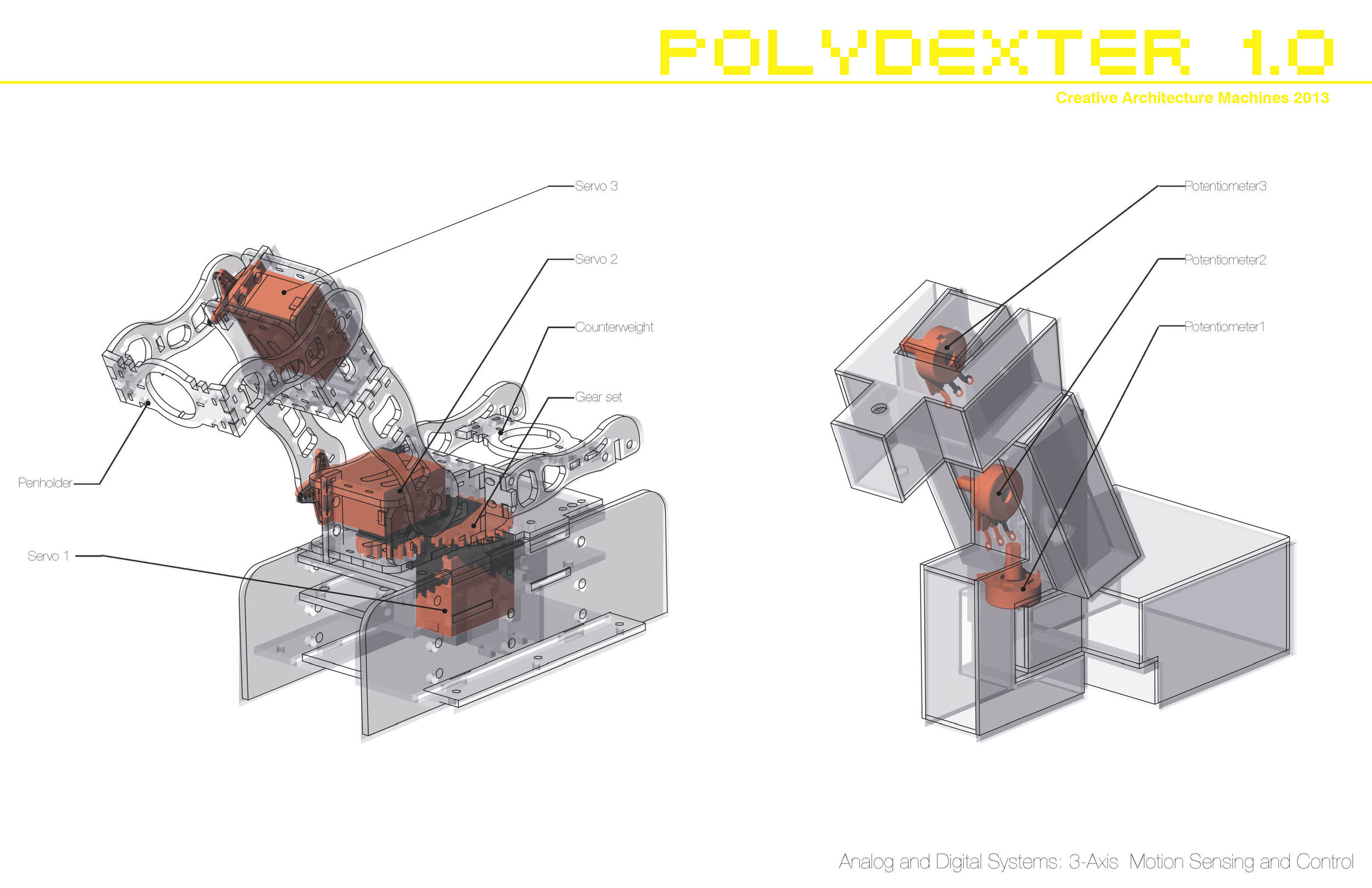

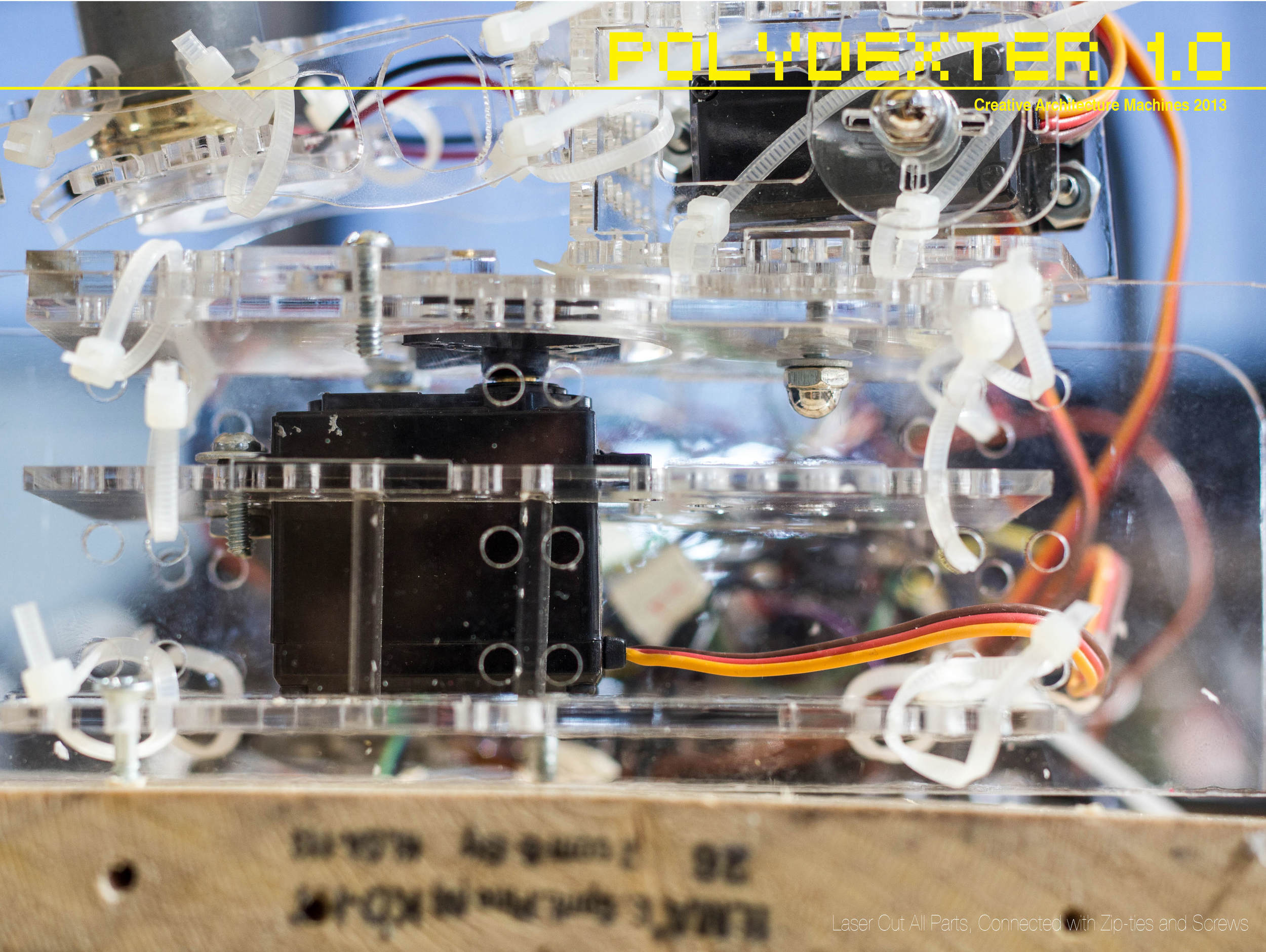

Materials: Laser-cut plywood, Servo motors, Custom extruder, Arudino Uno, Servo shield

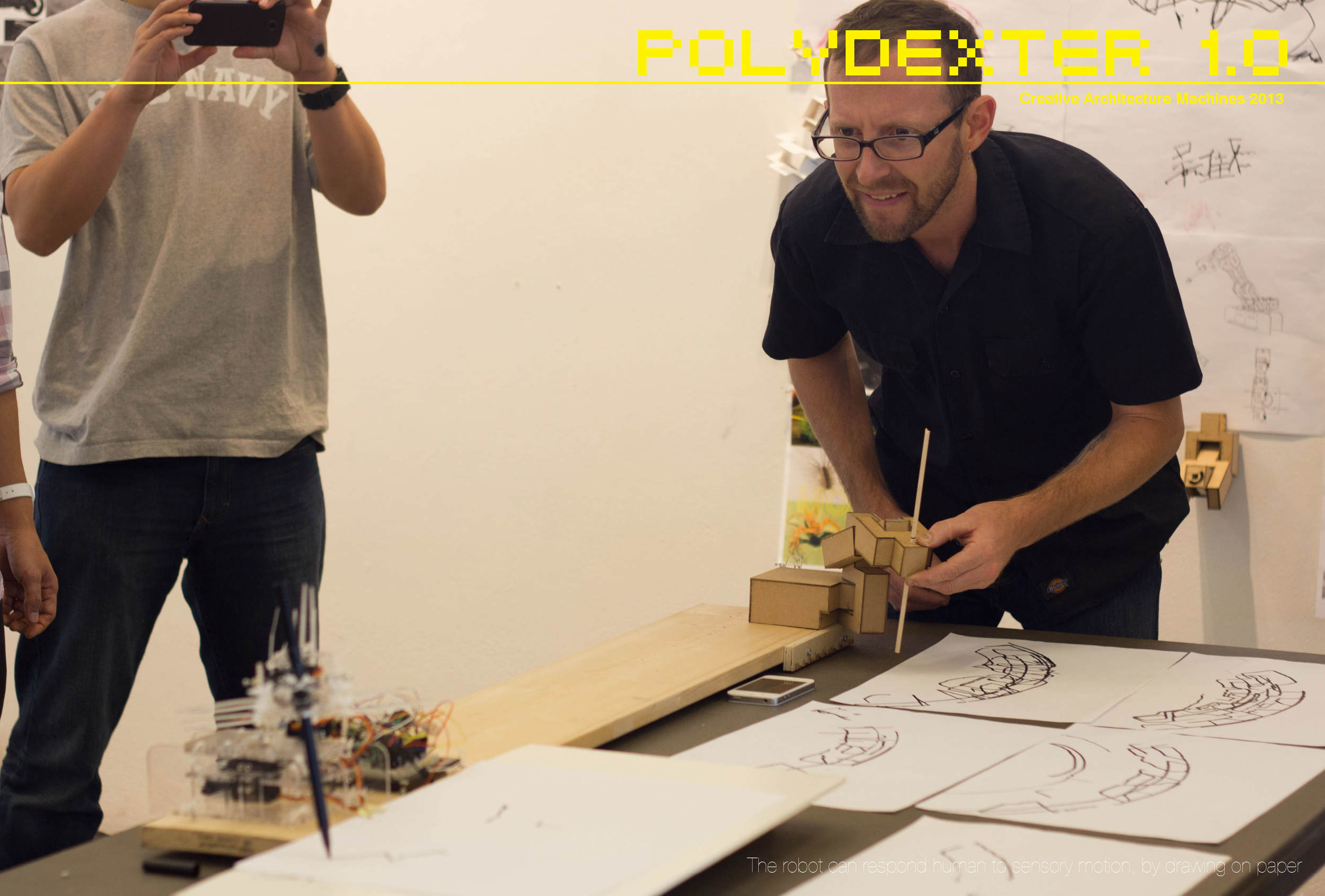

In the fall of 2012 I had the great fortune of being enrolled in Jason Kelly Johnson’s (co-founder of Future Cities Lab) Creative Architecture Machines advanced options studio at CCA. Co-taught with Michael Shiloh, a community manager with Arduino, this studio’s focus was on operational architecture through robotics. The first three weeks was concentrated on engineering a machine that produced two-dimensional drawings (the second project of the semester was a three-dimensional making machine, where we produced the world’s first walking 3D printer, Geoweaver). After a couple weeks of testing and Arduino workshops my partner Jia Wu and I had five days to design, prototype, wire, code, and build a working robot. In an effort towards open sourced learning and institutional memory we have posted instructions on how to build Polydexter on Instructables.

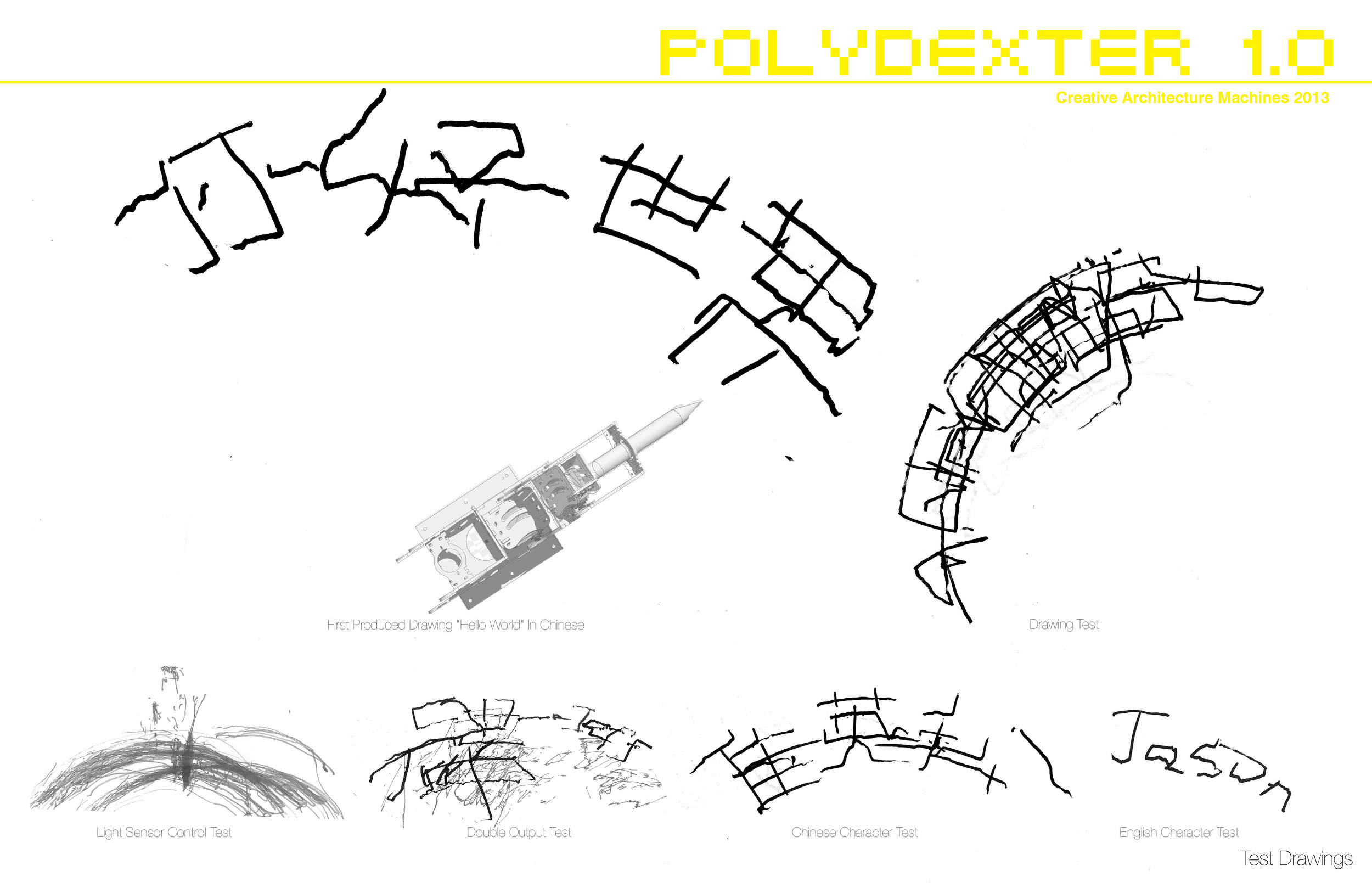

Our idea: Polydexter 1.0, a remote human sensing Arduino-controlled robotic translation arm. Utilizing three axes of control, the movement you put into the analog arm is augmented by the digital arm to produce a drawing by remote. We extrapolated a lot of possible uses: teaching people to write in different languages, translating/editing/censoring your written messages between countries, or, if scaled up, even translating a stroke of your hand into built space using precision brick laying or material extrusion. But more than any of that, it was a lot of fun to play with. I was apprehensive before joining this studio about how difficult electronics would be but we progressed exponentially in terms of robot making in those few weeks. A contest was held to see whose 30-second robot trailer could get the most hits on YouTube and our group won with a little under a thousand hits.